The_Observer

Member

- Messages

- 183

I came across a video that was explaining the history of precision and tools. It was very interesting. The foundation of precision is from the surface plate which can be created with 3 irregular planes, because the common plane between 3 irregular planes is a perfectly flat plane.

Anyways onto the point: Johannson gauge blocks. They were originally created as a basis of precision measurement to gauge your tools on a regular basis. It was more or less the beginning of standardization between measurements as up until that point, an inch was anywhere between 22-25mm depending on how it was defined.

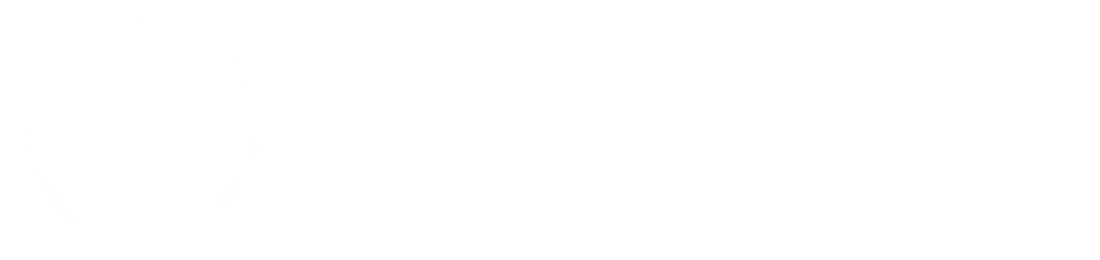

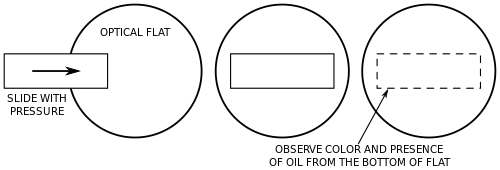

What I find so interesting about these blocks is that they are so flat and so precise in measurement, that they literally stick to one another seemingly without any explainable reason. No one knows if it's because of molecular adhesion, or the surfaces being so flat they press out all air and are sticking together through external atmospheric pressures; or a combination of factors.

I'm interested to see what input others have on these blocks and what you think makes them stick together?

Anyways onto the point: Johannson gauge blocks. They were originally created as a basis of precision measurement to gauge your tools on a regular basis. It was more or less the beginning of standardization between measurements as up until that point, an inch was anywhere between 22-25mm depending on how it was defined.

What I find so interesting about these blocks is that they are so flat and so precise in measurement, that they literally stick to one another seemingly without any explainable reason. No one knows if it's because of molecular adhesion, or the surfaces being so flat they press out all air and are sticking together through external atmospheric pressures; or a combination of factors.

I'm interested to see what input others have on these blocks and what you think makes them stick together?